Working to innovate the manufacturing process by achieving high quality and cost competitiveness.

A flexible board mounting line supporting a wide variety of board types, from thin to multi-layered.

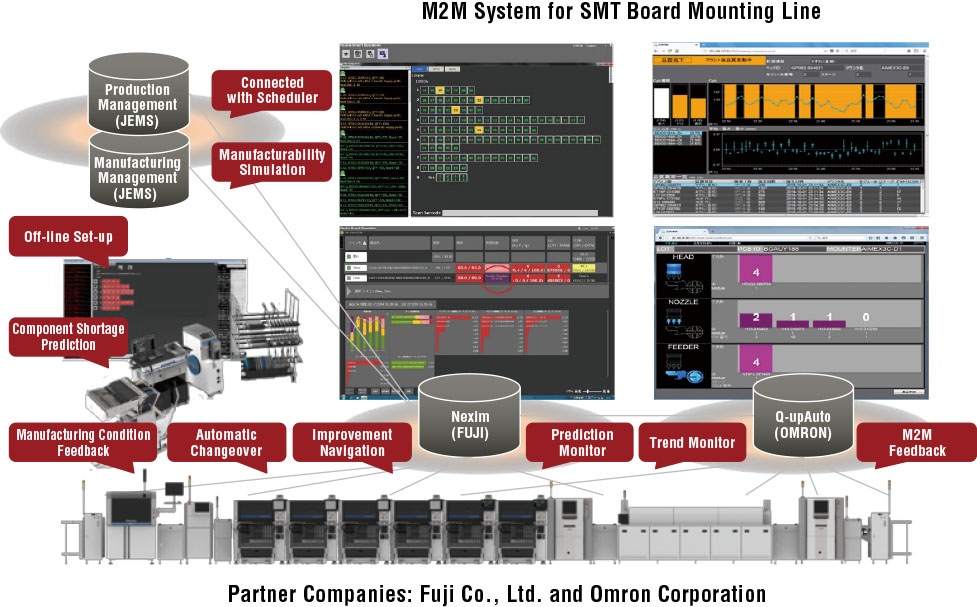

Board mounting needs vary, from thin boards to multi-layered boards. In order to support these diverse needs, we use cutting edge devices such as electrical component mounting robots, and X-ray inspection machinery. In addition, we are continually working with other equipment manufacturers to introduce the latest M2M systems on JEMS' site. Moving forward, we will be able to provide even more flexible support for smaller, thinner boards, and a wide variety of other demands, including development of our automated machinery in-house for secondary assembly.

Tools developed in-house ensure stable manufacturing.

In order to provide efficient, consistent manufacturing that eliminates waste, we developed our own automated machines, jigs, and prototyping machinery to handle assembly and prototyping. As such, we are able to ensure high quality, stable manufacturing without relying on workers, which prevents variability and human error.

Japan E.M.Solutions Co., Ltd.(JEMS)

Japan E.M.Solutions Co., Ltd.(JEMS)